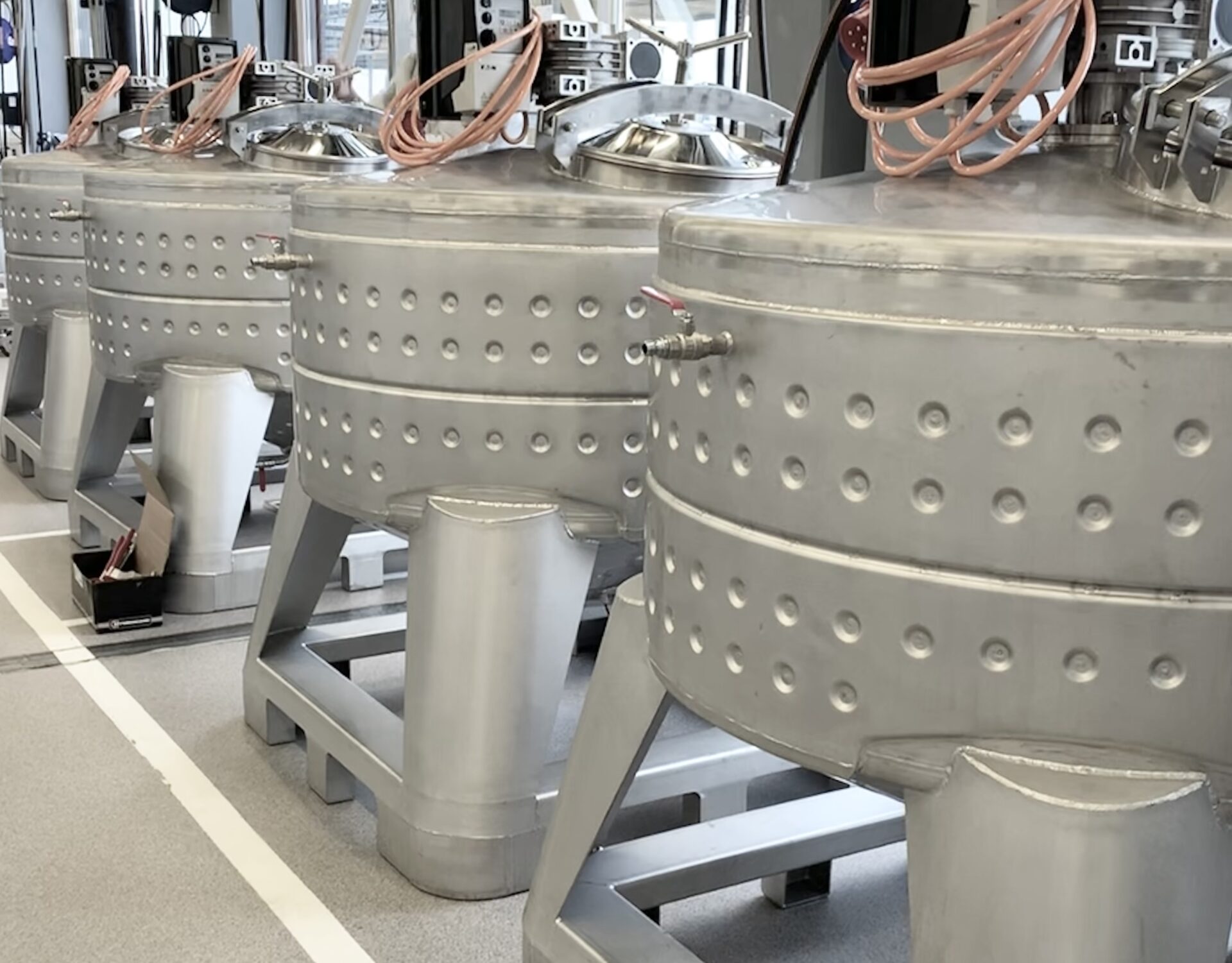

Engineering and Project Management by Thorsteel

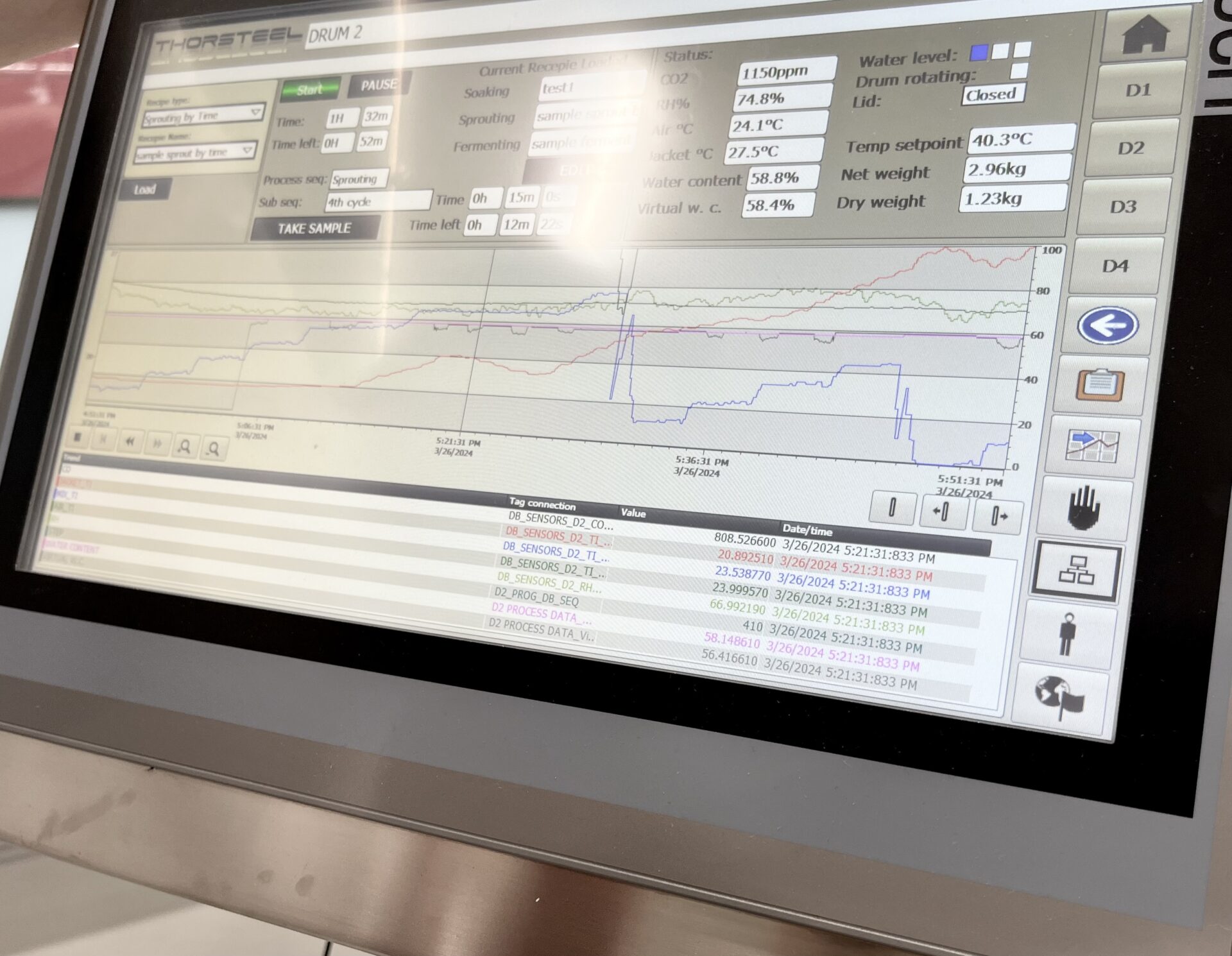

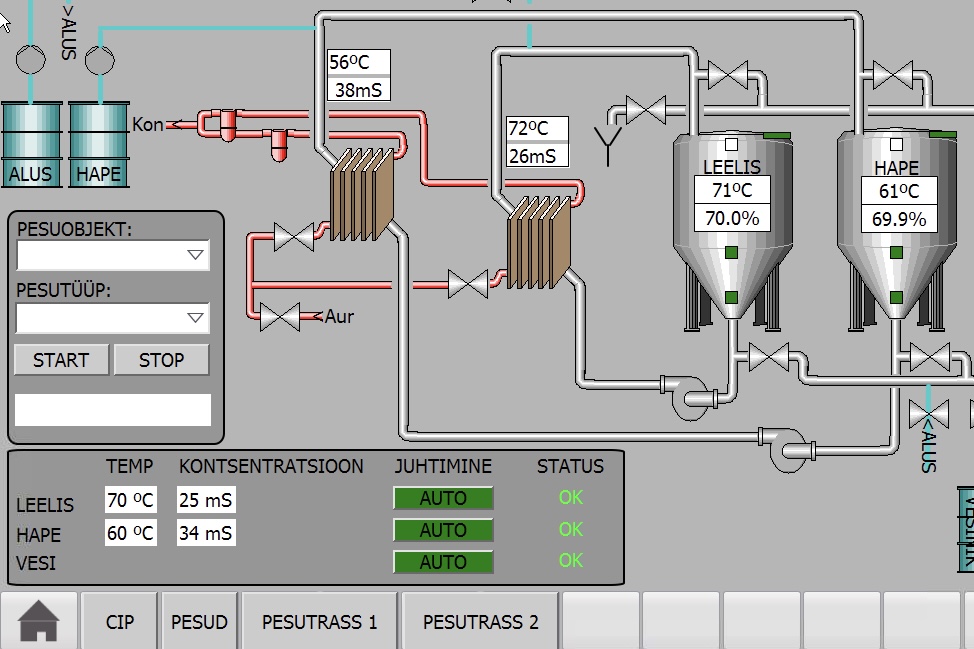

- Equipment R&D

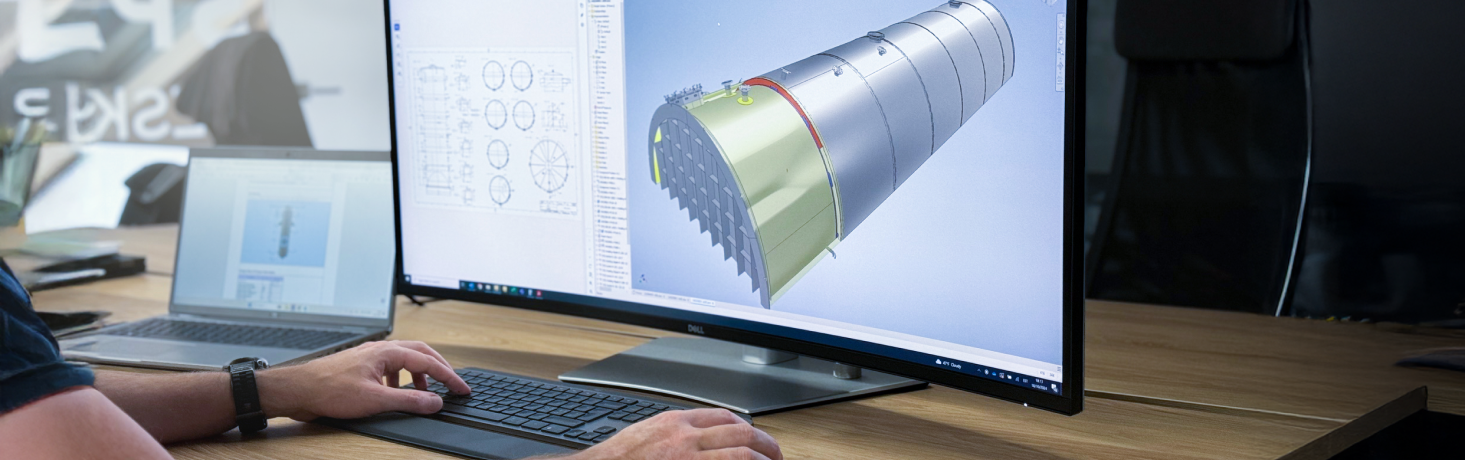

- 3D CAD modeling and drawings

- Pressure equipment calculations (ASME, PED)

- FEM analysis

- IWE competence

We develop a complete process solution with mechanics and automation.

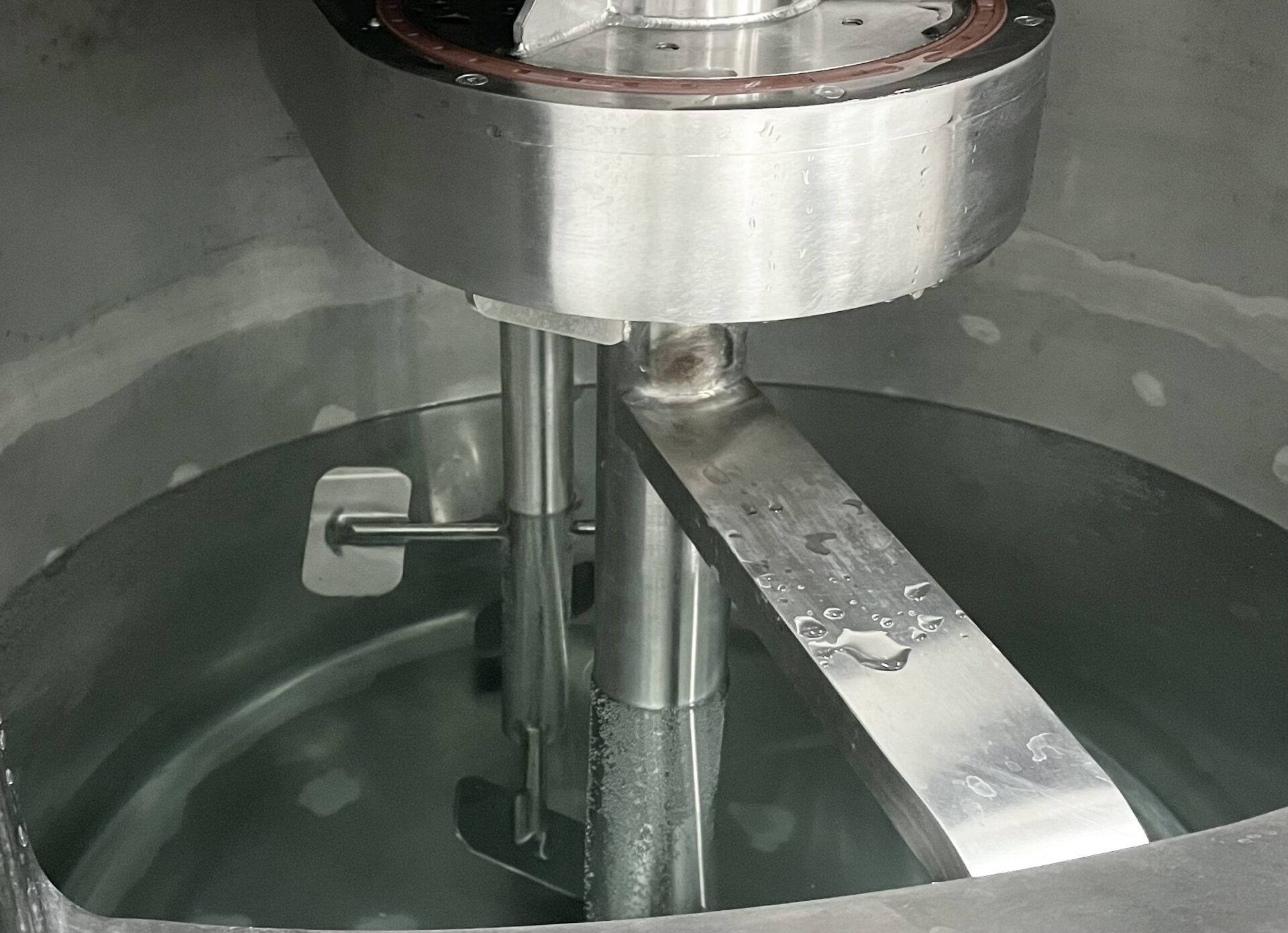

You can come with your special request for a mixing solution or a product that needs to be developed. We will map the situation and the client’s needs with on-site visits and careful planning.

Our engineering department is equipped with CAD software such as Inventor and Autocad, Vault for data management and collaboration, and PV Elite for pressure vessel design.